PRODUCTS > Rotary Wellpoint Pumps

PRODUCTS > Rotary Wellpoint Pumps

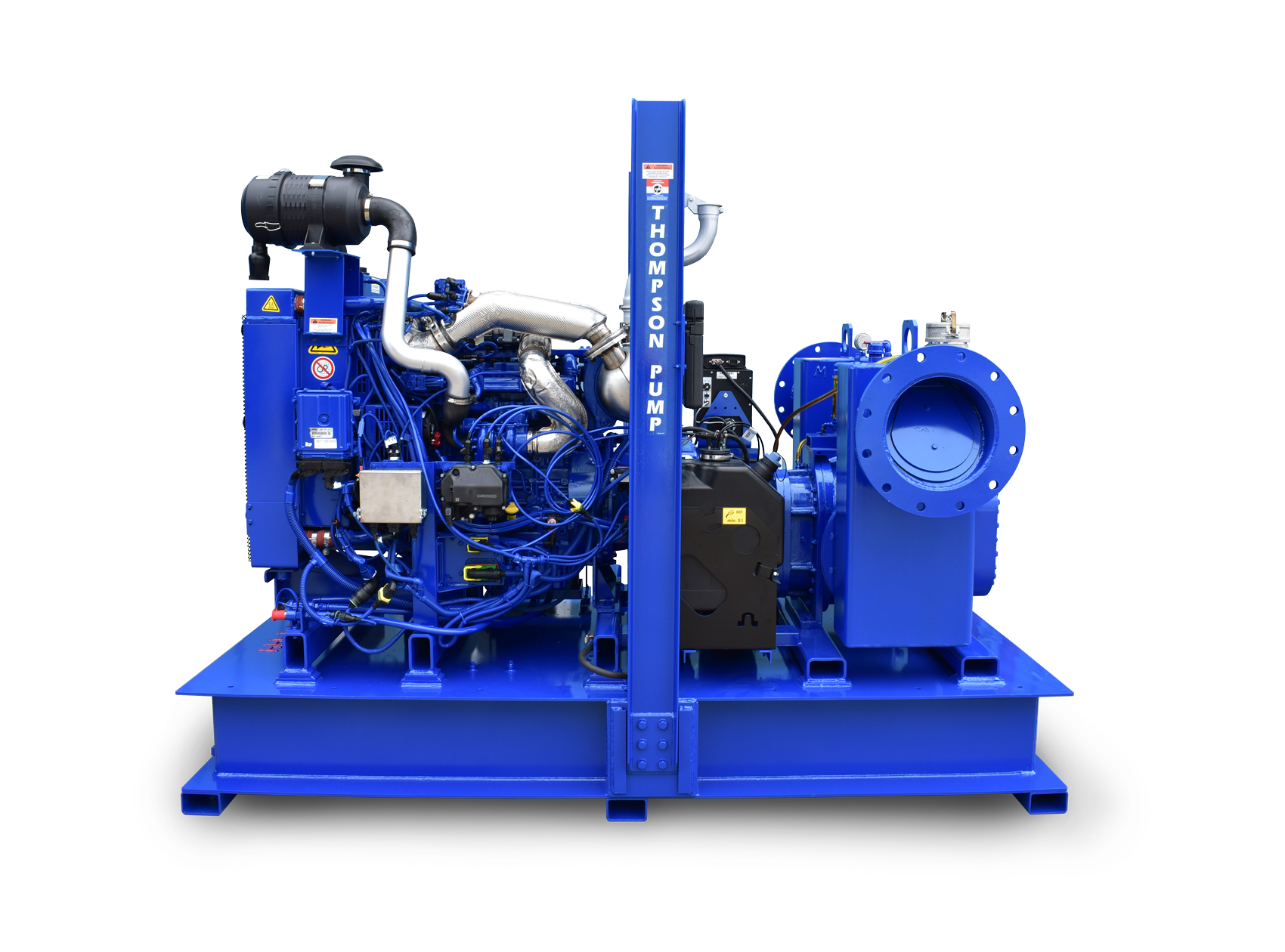

The original Thompson rotary wellpoint pump has been trusted by contractors worldwide for more than 50 years.

Thompson’s pumps are specifically designed and engineered for construction wellpoint and sock dewatering with high air handling, large water volume and high vacuum capability.

With 8-inch and 12-inch rotary pump sizes that handle both air and water, the positive displacement with constant suction makes this pump ideal for all wellpoint applications.

The Thompson rotary pump produces constant suction as the rotors separate. The liquid is directed around the rotors and out the discharge. The polyurethane rotors and the stainless-steel wear plates offer corrosion resistance while the steel inserts provide strength and durability.

Consult factory for other versions & options.

| Unit Model | Size (In.) | Max Head (Ft.) | Max Capacity (GPM) | Max Solids (In.) |

|---|---|---|---|---|

| 8RW | 8 | 120 | 1300 | Filtered Water Only |

| 12R | 12 | 120 | 2200 | Filtered Water Only |

Silent Knight®

Sound-attenuated canopy reduces pump sound levels to or below 69 dBA. Fully insulated, weather-proof and lockable, the Arctic Night® variation is ideal for extremely cold temperatures.